The rapidly expanding global market for all types of bioreactors for cell products makes it a highly lucrative field of science and technology that attracts major investments to accelerate the development of improved manufacturing practices. In recent years, the development of automated and semi-automated bioreactor systems has advanced rapidly to enhance the affordability, efficacy, and quality of various cell products. Expanding the scope of available technological solutions will allow for the manufacturing of a wide range of therapeutic cell products, including CAR-T cells, TILs, DCs, and NK cells (both autologous and allogeneic).

The fast-ever-growing field of immuno-oncology and customized cell therapies requires academic research and clinical facilities to accelerate the development to cover the unmet market needs [47]. However, the scaling up of the cell therapy industry is expected to result in a global manufacturing shortage that will mostly affect remote locations which are hard and costly to serve. We believe that the optimal solution to this problem is based on modular GMP-compliant bioprocessing units that will allow optimal allocation of resources and costs. The assembly of such units can be made fully automated to standardize and increase reproducibility of the whole process and reduce the user-associated risks.

Further advancements in both cell biology and hardware/software engineering will lead to more sophisticated closed automated POC platforms for rapid and cost-effective manufacturing of personalized cell immunotherapies. The POC systems are normally self-sustained and have lower infrastructural requirements which makes them more usable in various clinical settings. Such platforms are capable of regulating nutrient supply, medium exchange and waste removal. They also often include single-use disposable components and wireless sensors that monitor and record data in real-time.

The challenges that lie ahead of the scientific and biotech community, such as scaling up manufacturing of the cell products, automated monitoring, and sophisticated regulation of the whole process, will lead to the emergence of novel manufacturing platforms. Altogether, this eventually will transform the landscape from single institutions and small hospitals to an extensive and interconnected global network of manufacturing centers that will define the future of T cell therapeutics.

Source: https://www.mdpi.com/2306-5354/9/12/808

The FAI climbed 5.9 percent year-on-year in the first 11 months of 2018, quickening from the 5.7-percent growth in Jan-Oct, the National Bureau of Statistics (NBS) said Friday in an online statement.

The key indicator of investment, dubbed a major growth driver, hit the bottom in August and has since started to rebound steadily.

In the face of emerging economic challenges home and abroad, China has stepped up efforts to stabilize investment, in particular rolling out measures to motivate private investors and channel funds into infrastructure.

Friday's data showed private investment, accounting for more than 60 percent of the total FAI, expanded by a brisk 8.7 percent.

NBS spokesperson Mao Shengyong said funds into weak economic links registered rapid increases as investment in environmental protection and agriculture jumped 42 percent and 12.5 percent respectively, much faster than the average.

In breakdown, investment in high-tech and equipment manufacturing remained vigorous with 16.1-percent and 11.6-percent increases respectively in the first 11 months. Infrastructure investment gained 3.7 percent, staying flat. Investment in property development rose 9.7 percent, also unchanged.

English

English

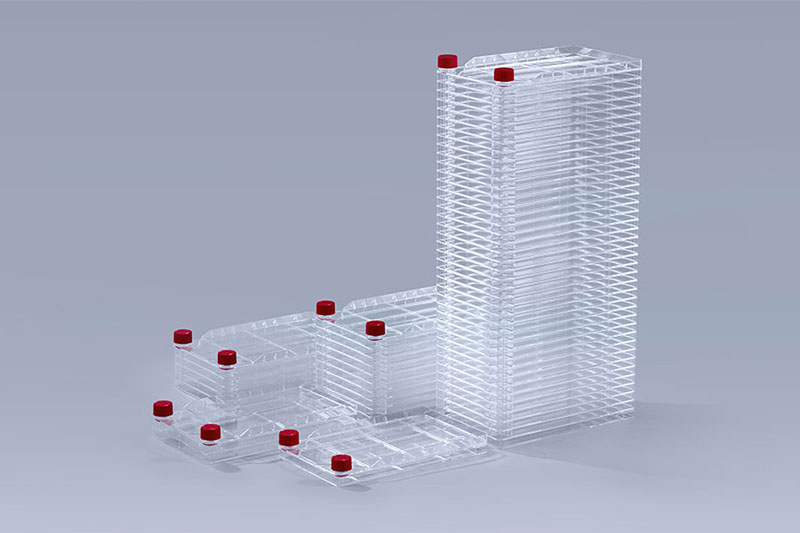

Cell Culture Flasks

Cell Culture Flasks PETG Media Bottles

PETG Media Bottles Cell Factory

Cell Factory